How To Repair A Sagging Header

How to Repair a Load-Begetting Post

Flooring sagging? Here'southward the solid cure for rotting posts and sinking footings.

![]() Fourth dimension

Fourth dimension

Multiple Days

![]() Complication

Complication

Intermediate

![]() Price

Price

$101–250

Introduction

Acquire to place the nearly mutual causes of floor sagging and what to practice about information technology. We'll show you the all-time tools and methods for lifting and shoring a load-bearing beam and the steps to safely supervene upon a rotted post.

Tools Required

Materials Required

- ½" dia. rebar

- 2 x 10 weight-spreader boards

- 4000 PSI concrete (minimum)

- Ballast bolt

- Physical plinth cake

- Heavy duty galvanized metal straps

- Heavy duty T-brace

- Joist hanger nails

- Sill sealer

- Wood post (iv x 4 or six x half dozen) for jacking

Sagging floors, doors that won't close and cracks that announced in interior walls tin be symptomatic of a more serious trouble. You may have undersized support beams, support posts that are rotting and losing their structural integrity, or undersized mail service footings that are settling. It's of import to cease this trouble and reverse it earlier it gets worse and becomes more plush to repair.

We'll prove you how to identify two common causes of flooring sagging, the all-time tools for lifting and shoring (temporarily supporting) a house beam, and the steps to safely replace a post. The actual work of repairing three to iv posts and footings takes 3 or four working days spread over 10 days. Add to that the time to program the work and obtain any required edifice permits.

Plus: Have you thought nigh removing a load-bearing wall in your home? Here's what you demand to know.

Raising the master beam that carries the floors and interior walls of a house is complex. Don't tackle it if yous're a novice. When you heighten a business firm even ane/two in., the effects tin can ripple through the building's framing, plaster walls, rigid piping and chimneys. For this reason, only specialty contractors should raise a beam or wall more than nigh 1 in. or undertake extensive floor leveling.

Project step-by-footstep (fifteen)

Step i

Identify the Problem

Floors sag considering the load begetting posts supporting a house beam are declining and/or the footings property those posts are undersized and sinking. Diagnose the problem by seeking the easiest solution start; go further but equally needed. If your posts direct contact the floor, start by using a screwdriver to probe the base of your wood posts to reveal any rot that could have caused them to settle.

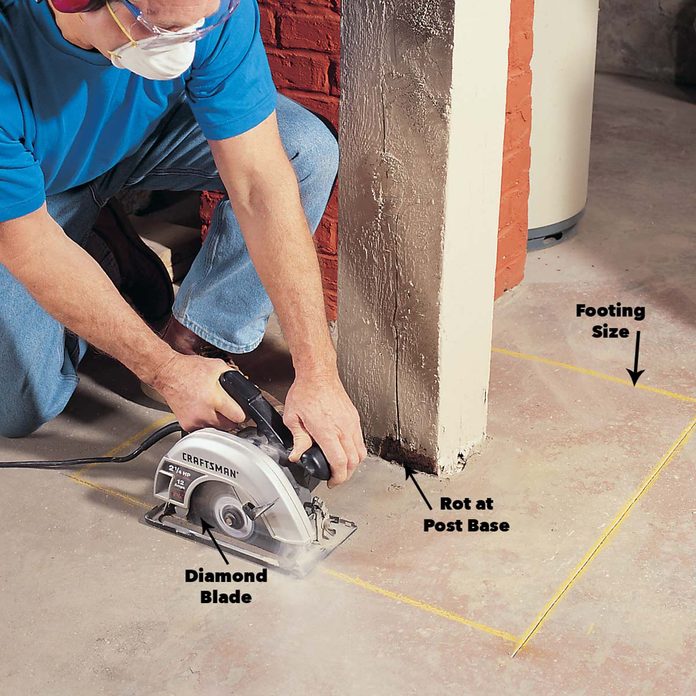

If the post isn't rotting, the physical footing it'southward on is nearly certainly sinking or has deteriorated. Compare the old basis's dimensions with an engineer's recommendations and current code requirements. To get at the footing, you'll accept to saw through and strip off the concrete floor covering it, then dig down ane side of the footing until you lot can measure its length, width and thickness. The 7-one/4 in. round saw we used won't cutting through slabs more than 2-1/2 in. thick. For cutting through thicker slabs, rent a xiv-in. concrete saw fitted with a diamond blade. Hang plastic sheeting to block migrating dust.

To begin cutting out the quondam flooring, mark the size of the new footing and cut the outline with a circular saw fitted with a diamond masonry bract. Start by making a ane-in. deep plunge cut on each side of the post. Brand successively deeper ane-in. cuts until soil pulled from underneath the slab tells you the concrete has been breached.

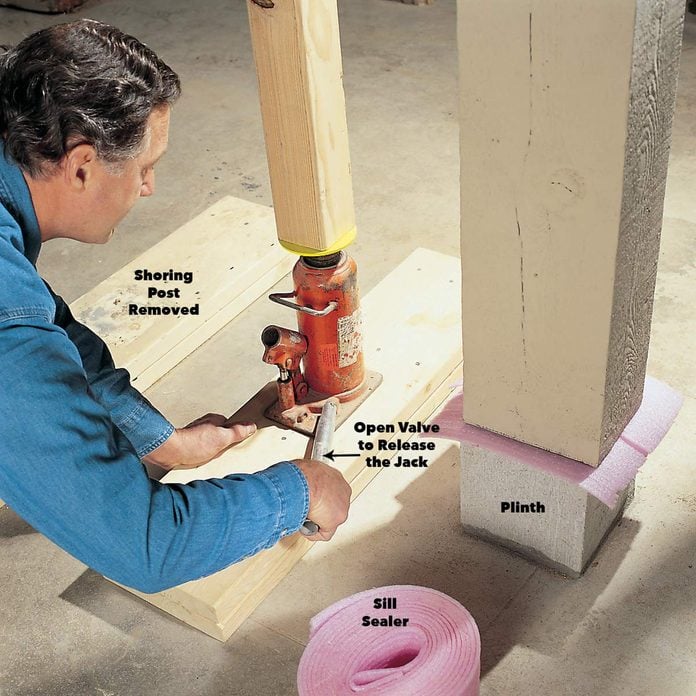

Our floor sagging occurred because the post bottoms had rotted and the footings were undersized. Too pouring new footings and restoring the posts, we added plinth blocks to elevate the wood to a higher place moisture on the basement floor.

Step 2

Get Adept Communication

Posts and footings back up the weight of your business firm, so you have to size them correct. Load-bearing posts must have a solid footing on undisturbed soil, and all parts of the postal service must be fastened together. Consult with a structural engineer, local building officials and contractors who specialize in this work. Hire the professionals to review all aspects of your project and provide the calculations and drawings necessary to obtain a building let (Fig. A, shown above). Interview those who do residential work and take experience with this blazon of project. You can look them to:

-

- Evaluate soil and its load-bearing capacity.

- Examine your house to identify possible bug from jacking it.

- Calculate proper ground, axle and load begetting post sizes.

Review your work plan. Show them the ceiling jack, shoring posts and spreader boards you intend to use to make certain they're sized to lift and safely hold your business firm beam.

Step 3

Separate Pipes From the Beam and Prepare for Lifting and Shoring

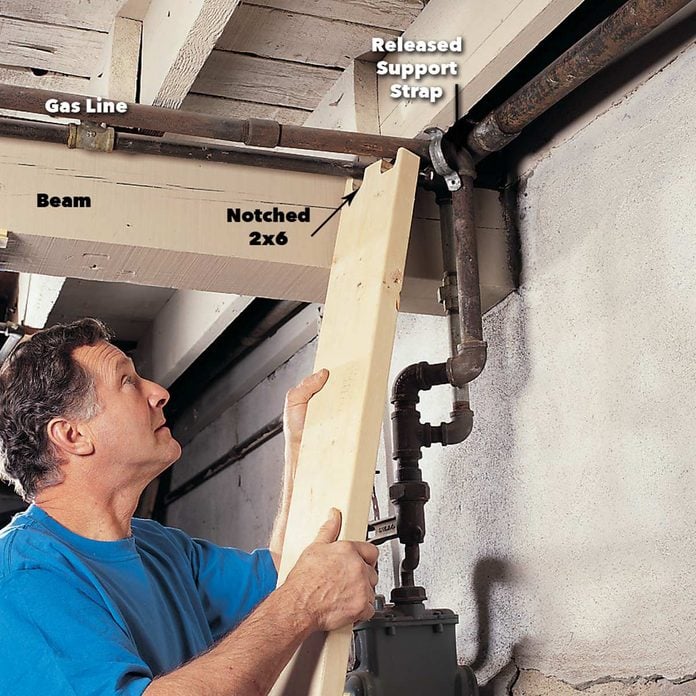

Release all rigid connections between gas, heating, plumbing or electrical lines (in conduit) and the house beam. To avoid rupturing these lines while the beam is being raised, support them with a 2x6.

Repair or replace posts or footings by raising the beam with a hydraulic jack and 4x4 mail, then shoring information technology with adjustable steel posts. Buy a hydraulic jack and rent the shoring posts for the projection. If yous're removing and resetting more than than one basement post, use one hydraulic jack and motion from station to station equally yous install and later remove the shoring posts.

As a house beam is raised, any rigid plumbing, gas, electrical or heating lines in the basement continued to the axle, the floors or walls higher up could rupture. Before jacking the beam, release the connectors holding these lines and back up them with lumber resting on the basement floor. To monitor the total rising during lifting, mensurate and write the floor-to-beam heights on the beam where hydraulic jacks volition exist placed. So remove or cut whatever nails, screws or straps that join the load bearing posts to the axle.

Stride 4

Place the Hydraulic Jack

To avoid bang-up the basement floor, lay 2 "weight-spreader" boards under hydraulic jacks and shoring posts. The boards should be ii 3-ft. long 2x10 boards a minimum of six in. from the sides of the hole. Place the boards apartment and level to ensure a safe lifting base for the jacks and posts. Then center a hydraulic ceiling jack directly under the axle's lifting betoken using a plumb bob. Make sure the jack is perfectly plumb and sits solidly level on the boards. If you lot have a concrete floor less than 2 in. thick, ask the engineer if yous should substitute thicker lumber to prevent floor not bad. Check along the cut edge of the concrete floor for voids that would collapse under lifting pressure level. If you lot find whatsoever, ask the engineer for remedies to the problem.

Jacks apply tons of hydraulic force to lift the wood jacking mail and axle, so select a nearly knot-free Douglas fir or Southern yellow pine 4×four. Don't use 2x4s or weaker woods like cedar or redwood. Use a 6×vi if you lot're jacking houses with 2 or more stories.

Step 5

Set the Jacking Post

One time the spreader boards are laid and the hydraulic jack is set in identify, cut the 4×4 or 6x6 jacking mail to fit between the jack piston and the beam. Measure the top betwixt the support beam and the top of the jack's lowered piston, and then deduct 1/2 in. and cut the post to length. Place a i/iv-in. thick steel plate between the piston and the lesser of the load begetting post to foreclose the piston from becoming embedded in the mail service. Snug the postal service upwards to the beam by closing the jack'southward release valve and pumping the jack handle upward and downwardly to raise the piston.

Pace 6

Center a shoring mail on its spreader boards nigh 12 in. from the 4x4 jacking post. Then lower the mail's screw head to its lowest position, raise the telescoping sections as loftier as they'll go under the beam and insert the metal pins to lock the sections together. Enhance the spiral head to its centered position nether the beam and attach the meridian plate to the axle with duplex nails. Now you lot're gear up to lift.

Step 7

Safely Lift the Beam

Enhance the house beam by pumping the hydraulic jack very slowly using short strokes. Raise it no more than than ane/2 to 1 in. total to release the weight from each post. Measure from the floor to the beam to monitor the axle's rise. Have an assistant simultaneously raise the shoring post as tight equally possible against the beam to provide fill-in load support. When the old mail loosens, remove and characterization information technology for reuse.

I take never lifted a business firm beam without having the hairs stand upward on my neck as I pumped the jack and heard the beam, floors and walls above groaning in response. Earlier lifting, double-check your equipment, visualize your plan and think safe. Follow these rules:

- Only apply shoring posts rated to behave your beam load. Hire whatever blazon exceeds the load specified past the structural engineer.

- As the hydraulic jack lifts the axle, turn the handle of the shoring post to proceed the post head tight to the beam.

- Only use shoring posts to support a beam while work is underway. Never use hydraulic jacks as shoring devices. Jacks may accept defective internal seals that could leak hydraulic fluid and crusade the jack to sideslip and driblet the load.

- Raise the beam just until the post is released. One time the load is released from the onetime mail, accept an assistant remove the post. And so characterization both its top terminate and its location along the axle for exact repositioning afterward.

Footstep eight

Dig the Footing

If yous accept to replace undersized footings, it'southward time to excavate, place steel reinforcing rods and pour concrete for them. With the post removed, suspension out an undersized footing with a sledgehammer and shovel (wear goggles and gloves) and pour the new i.

Excavate the basis hole to the specified size, digging the sides and bottom of the hole square and level. Scrape loose soil from the bottom of the hole until y'all reach the undisturbed soil. If the soil caves in along the edges, install 1/two-in. plywood to hold the dirt back. Remove them while pouring the concrete. As shown above, during excavation, make a depth estimate to ensure a basis with compatible thickness and a level lesser.

Step ix

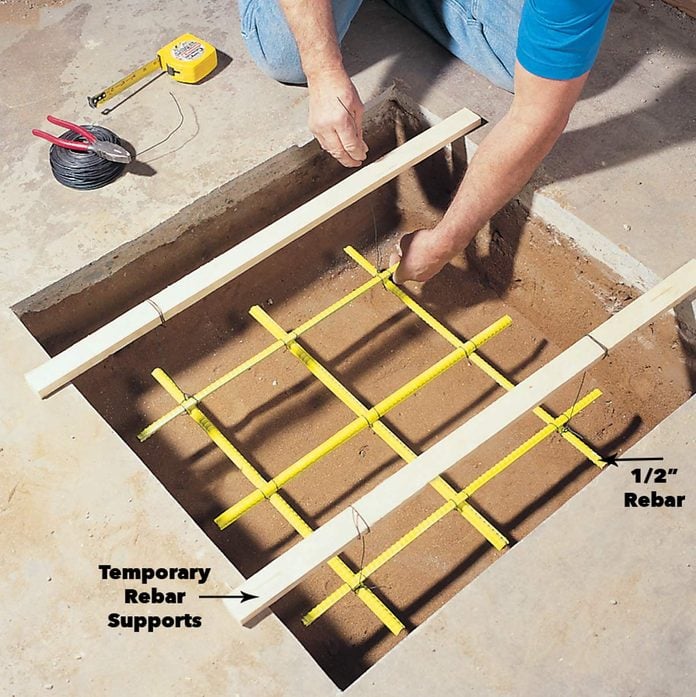

Place the Rebar

Install rust-free, 1/two-in. dia. reinforcing rod (rebar) to strengthen the physical basis. Buy 2-ft. lengths of 1/2-in. rebar at home centers. Next, append the rebar in the lower tertiary of the footing and necktie the rebar together using sixteen-gauge wire.

Step 10

Pour the Footing

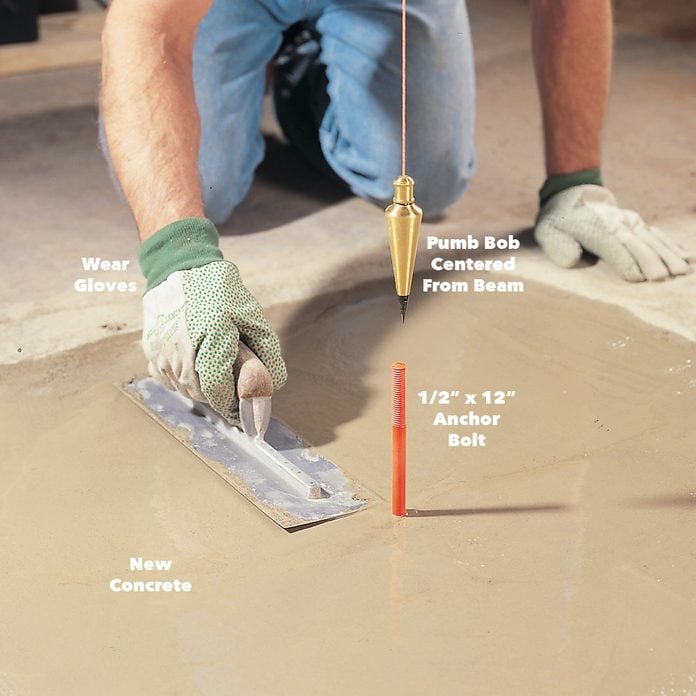

Pour concrete into the hole to the level of the existing floor and smooth information technology with a steel trowel. Select concrete with a minimum compressive force of 4,000 psi (check the packaging, or social club it that way). For maximum strength, add only the amount of water specified by the manufacturer. Also, be sure to mix and cascade all the concrete for each footing in less than ane hour then that the batches bail well. Finally, suspend a plumb bob from the post'southward center bespeak under the beam above and identify a 1/ii-in. x 12-in. anchor bolt in the wet mud. Our anchor bolt rises 6 inches out of the concrete.

Step 11

Identify the Pinch Block

Level an 8x8 concrete block in freshly laid concrete, centering information technology around the anchor bolt. Completely fill up the core with concrete. Save time by setting the plinth block on a still-wet footing once the physical tin back up the weight of the block. To adjust our 6x8 wood post, we used a standard 8x8 half-corner block. Make certain your plinth is at to the lowest degree equally large as your mail.

Step 12

Reinstalling the posts

Install the post on a new plinth and basis only after the concrete has cured for 7 days. Wood posts are easier to work with, and then stick with wood rather than metal. Dwelling house centers and lumberyards acquit steel "mono-posts" and steel posts with telescoping sections, but you demand special skills and techniques to properly back up forest beams with steel posts. Consult with engineers and/or local building officials earlier using them.

Your local edifice officials may insist yous install only new, pressure-treated 6x6 posts set on plinths. We had no such restrictions and reused our old woods posts considering they were yet tall enough afterward sawing off the rot. If this is the case for you likewise, mensurate the height betwixt the house beam and the plinth, decrease 3/16 in. and cut the erstwhile basement postal service to length. Saw a squared bottom from the rotted finish, using a circular saw to girdle the mail service. Terminate the cutting with a handsaw.

Step 13

Set the Post

Nigh former posts don't take a foursquare, level top. Don't change that. For the best contact and load transfer, reinstall the posts exactly in their original position nether the business firm beam, with all those old irregularities fitting like a manus in glove. To prevent any wet from wicking into the mail from the plinth, lay sill sealer or galvanized sail metal between the two. Set the post on its plinth cake, matching the postal service top to its prior contact position with the house beam. Then reset the hydraulic jack, lower the shoring post, and very slowly open the valve of the hydraulic jack to carefully lower the beam onto the post.

In your excitement to reset the posts and finish the job, don't take risks. Use an assistant and lower the ceiling jack very slowly, leaving the shoring in place while putting weight onto the posts.

Step xiv

Anchor the Post to the Plinth Block

Using a hammer drill fitted with a masonry bit, predrill two three/xvi-in. holes 1-i/four in. deep into contrary sides of the plinth block. Install 1-1/4 in. concrete screws through metal anchor straps into the plinth and then boom the straps to the wooden post with galvanized 10d box nails.

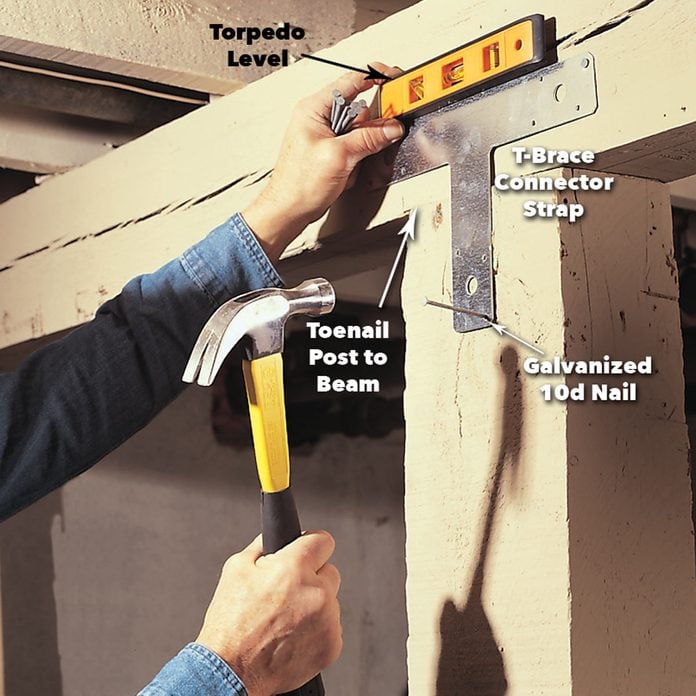

Step 15

Fasten the Beam and Mail service Together

Bring together the back up beam and wood load bearing post by toenailing them together and attaching two metal T-braces to opposite sides of the beam with galvanized 10d box nails. Once that's done and the back up strapping is reinstalled on all gas, electrical, plumbing and heating lines, y'all'll have the satisfaction of completing a task that volition concluding for the life of the house.

Plus: Learn how to install a load-bearing axle here.

Source: https://www.familyhandyman.com/project/how-to-repair-a-load-bearing-post/

Posted by: aguirresplight.blogspot.com

0 Response to "How To Repair A Sagging Header"

Post a Comment